Purification & Bottling Plants

Biogas Purification Plant

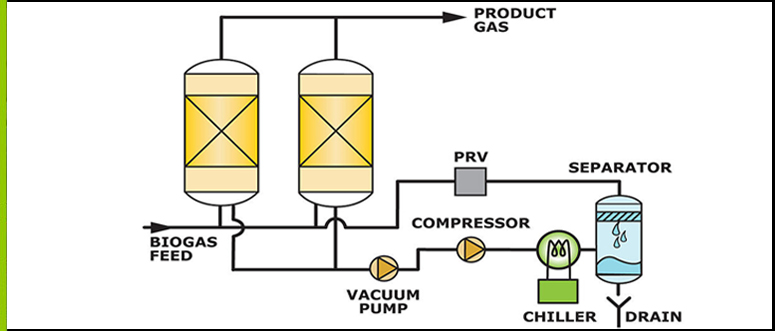

As an esteemed company, we are engaged in providing a wide array of Purification Plant. The given purification plant is developed by team of professionals using best grade material and latest techniques in compliance with market norms. Our offered purification plant is comes with twin tower P.S.A. module with automatic pneumatically operated changeover valves.

Standard Scope of Supply:

* Air intake after cooler, moisture separator, pre-filter, audio drain valve & wet air receiver

* Twin tower desiccant based air dryer fully automatic with pneumatically operated changeover-valves (REF Dryer- Optional)

* Dry air receiver with pressure gauge, pressure switch and candle type after filter

* Twin tower P.S.A. Module with automatic pneumatically operated changeover valves, pressure gauges & interconnecting piping

* Surge Vessel with instruments & drain Valve

* Z.M.S. (Zeolite Molecular Sieves) one charge filled in P.S.A. Adsorption Towers

* Flow meters for oxygen with flow control valve, NRV and Back pressure Controller

* Centralized control panel with sequence programmer and fault Indications Lamps

* Online Methane & H2S Analyzer .

Upstream Equipment for Raw Biogas feeding system:

* Feeding Blower

Specifications:

* Capacity: 50 m³/h- 5000 m³/h

Features :

* Long working life

* Smooth functioning

* Noiseless operation

Biogas Bottling plant :

Purification of biogas by vacuum pressure swing adsorption was evaluated to produce fuel grade methane (FGM). Two different adsorbents were employed to evaluate the process performance with equilibrium- and kinetic-based adsorbents. Carbon molecular sieve 3K was employed as the example of a kinetic adsorbent because methane diffusion is extremely small. A five-step cycle configuration (feed, intermediate depressurization, blow down, purge, and pressurization) was employed to compare with results obtained with a four-step cycle without intermediate depressurization. The effect of different operating variables like step times and pressure conditions of the cycle was analyzed.

A solid value proposition for biogas operators: Biogas producers who utilize the Biogas Optimizer service will be able to experience:

* Higher biogas production (a better utilization of digester capacity)

* A more stable biogas production (thus able to maximize ROI on CHP or gas upgrading units)

* Protection against process disturbances and better management routines to avoid process problems

* Detailed process monitoring and diagnosis leading to a cost efficient plant operation

* A faster start-up of bioreactors